Introduction: (written

9-3-06)

This

circuit detects sound through a microphone and converts it to a DC voltage

proportional to the audio wave amplitude.

I

originally designed this sensor to measure my car engine's rotary speed (RPM)

by the volume of sound it produced - I wanted to avoid physical interfacing

with my engine's electronics, of which I knew little about at the time.

However, numerous conditions (that I won't bother mentioning) make this an undesirable

sensor for my automotive application, so I researched engine electronics and

found the perfect electrical parameter to interface with for a precision

RPM-to-voltage converter (Engine-Controlled

Power Circuit).

But

this sound amplitude detector can still lend it's service to applications used

in less extreme environmental conditions

Automotive Sound Level Sensor

Devin

R Ott

Design

- completed in August 2004

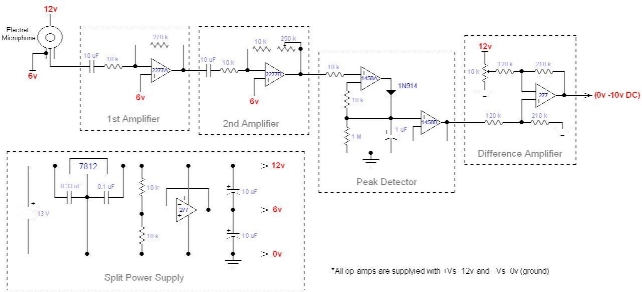

Click on schematic

for larger view

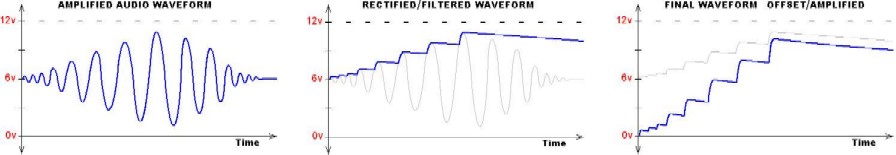

This circuit uses an electret microphone to

convert the audio engine noise to an electrical AC signal that fluctuates

above/below 6 volts. This signal is sent through two amplifier stages

built around the OPA2277 dual op-amp, providing an adjustable voltage gain from

27 to 675. The series RC inputs of these amplifiers create a low cut-off

frequency of 1.6 Hz, allowing them to block DC while amplifying audio frequencies.

The 2nd stage can be adjusted to output a maximum 6 volt amplitude

when the engine is loudest, creating a 0 to 6 volt AC amplitude that changes

proportionally with the engine noise.

The AC signal is then rectified and filtered

by the peak detector which smoothes out the positive peaks and represents the

signal as it’s 6 to 12 volt DC equivalent. In reality, the peak detector’s

1458 dual op-amp is not equipped with rail-to-rail outputs, so the real output

voltage range is from 6 volts to about 11.7 volts DC.

This voltage range is then sent to a difference

amplifier (OPA277 single op-amp) that subtracts about 6 volts from it, and

amplifies the result by a 1.75 voltage gain. The subtracted voltage reference

is programmed by a 10k pot, allowing one to account for the minimum engine

noise level.

When the engine is off (no

noise) the output of the peak detector is 6 volts. However, when the

engine is running in the idle position (minimum noise) the peak detector is

outputting 6.5 volts. By adjusting the subtracted voltage to 6.5 (instead

of 6), the difference amplifier would output zero volts when the engine noise

was minimum (no throttle), and about 10 volts DC when the noise was maximum

(full throttle).

The entire circuit is

powered by the car battery voltage, which is immediately filtered and

stabilized by the 12 volt regulator. The AC amplifier stages of this

circuit require a dual polarity supply, so an OPA277 single op-amp has been

configured to regulate its output at ˝ the supply voltage (6 volts DC). This

voltage acts as a ground reference, while the 12 volt and 0 volt potentials of

the regulator are supplying ±6 volts relative to that reference. So the

AC signals are fluctuating above and below 6 volts DC, relative to the ground

potential of the car battery.

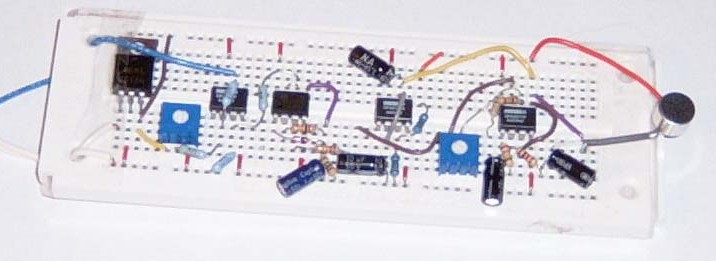

Prototype:

Back to my EE Page

Back to Home

© 2006,

Devin R. Ott